Xawaaraha dib-u-warshadeynta gawaarida korantada

Xawaaraha yareeya matoorka korantada, yareeyaha mishiinka korantada, yareeya xawaaraha korantada, mishiinka korantada

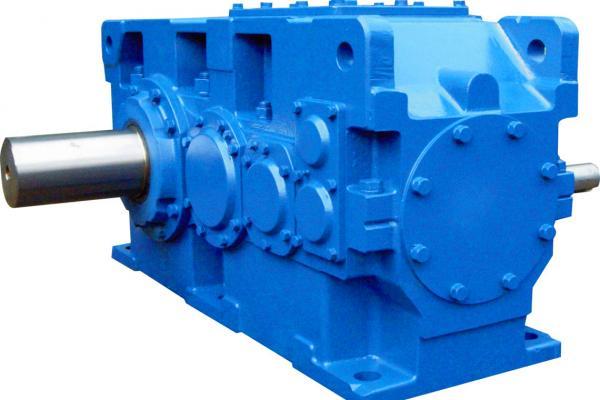

Taxanaha k ee xawaaraha xagal toosan ee mishiinka korantada ee wax soo saarka gear-ku waa isku darka marsho helical oo heerar badan leh, kaas oo ka waxtar badan marka loo eego xawaaraha marshada gooryaanka hal mar ee matoorada korantada.

Xawaaraha yareeya matoorka korontadu waxa uu ka kooban yahay biraha, gears iyo shafts kuwaas oo kuxiran guri warshad ku rakiban tahay. Waxay si toos ah ugu rakiban karaan matoor ama kaliya shafka. Xawaareheenna gawaarida korantada waxay ku habboon yihiin alaab-qaadayaasha, maaraynta alaabta, mashiinnada dunta, mashiinnada baakadaha, iwm. (xawaaraha gaabis ah iyo wareegga sare).

Xadka awoodda: 0.12- 200KW

Kala duwanaanta raashinka gudbinta: 1.3-33000

Wax soo saarkii (Kn.m): kor ilaa 50

Xawaaraha taxanaha k ee matoorka korantada waxaa loo qaabeeyey iyadoo lagu salaynayo nidaamka isku dhafka moodada. Waxay leedahay tiro aad u badan oo ah isku-dhafka mootada, boosaska rakibida iyo xalalka qaabdhismeedka. Waxay leedahay hufnaan labajibaaran oo sarreeya iyo qalab nololeed oo sarreeya. Waxay ku qalabaysan tahay dhejinta cagaha, dhejinta flange iyo rakibida shafka.

Ka hel heshiiska ugu fiican ee xawaaraha dhimista ee matoor koronto ka soo saaraha xulashada khadka ee ugu weyn. Ku baadh qiimo jaban oo bilaash ah alaabooyin badan oo xawaaraha dhimaya mishiinka korontada

K taxane gear yareeya, oo ay weheliyaan shuruudaha farsamada caalamiga ah, waxa uu leeyahay content farsamo sare; badbaadinta meel bannaan, la isku halayn karo oo waara, leh awood xad dhaaf ah, awood ilaa 132KW; Isticmaalka tamarta yar, waxqabadka sare, waxtarka yareeya ilaa 95%.

K series Spiral bevel gear gear yareeya mishiinka korantada, R taxane helical gear yareeya dusha adag, F taxane is barbar shaft helical gear yaraynaysaa, S taxane helical qalab yareeya gear gear, T taxane Spiral bevel gear yaraynaysaa ee mishiinka korantada, oo leh yar yar jirka, Durdurada gudbinta waa weyn.

Naqshaday oo la soo saaray iyadoo lagu salaynayo nidaamka isku dhafka modular, waxaa jira iskudhafyo badan oo matoor ah, foomamka rakibaadda iyo nidaamyada qaabdhismeedka. Saamiga gudbinta si fiican ayaa loo qiimeeyay si uu ula kulmo xaalado shaqo oo kala duwan oo loo xaqiijiyo is-dhexgalka elektiroonigga ah.

Afarta taxane ee xawaaraha dhimista ee r, k, f iyo s waxay qaataan mabda'a naqshadaynta qaabdhismeedka cutubka, taas oo aad u yaraynaysa noocyada iyo agabka qaybaha, aadna u gaabinaysa xilliga dhalmada.

Waxtarka gudbinta sare, isticmaalka tamarta yar iyo waxqabadka sare.

Sanduuqa birta ah ee adag ee adag oo leh feeraha; Qalabka ilka adag ayaa laga sameeyay bir tayo sare leh, dusha sare waxaa lagu adkeeyey carburizing iyo deminta, ilka shiididda si fiican ayaa loo farsameeyaa, gudbintu waa deggan tahay, sawaxanku waa hooseeyaa, awoodda xajintu waa weyn tahay, kor u kaca heerkulka waa hooseeyaa. , iyo nolosha adeeggu waa dheer yahay. Waxqabadka iyo sifooyinka:

1. Qalabku wuxuu ka samaysan yahay carburizing alwaax tayo sare leh iyo deminta, engegnaanta dusha iliggu waa ilaa 60 ± 2hrc, iyo saxnaanta dusha sare ee iliga waa ilaa 5-6.

2, iyadoo la adeegsanayo tignoolajiyada dib-u-qaabaynta kumbuyuutarka, dib-u-habaynta hore ee qalabka, si weyn u wanaajisay awoodda culeyska

3, laga bilaabo santuuqa ilaa qalabka gudaha, iyadoo la adeegsanayo qaab-dhismeed qaab-dhismeed dhammaystiran, oo ku habboon wax-soo-saarka ballaaran iyo xulashada dabacsan

4. Qaabka dhimista caadiga ah waxaa loo qaybiyaa si waafaqsan foomka dhimista qulqulka. Marka la barbar dhigo saamiga dhaqameed ee siman, waxay ku badan tahay shuruudaha macaamiisha waxayna ka fogaanaysaa qashinka korontada.

5, iyadoo la isticmaalayo cad / cam design iyo wax soo saarka si loo hubiyo xasiloonida tayada

6, iyadoo la adeegsanayo qaabab kala duwan oo wax lagu xiro si looga hortago daadinta saliidda

7, tallaabooyinka dhimista buuqa jihooyin badan si loo hubiyo waxqabadka sanqadha hoose ee ugu fiican

8. Habka rakibaadda alaabta ayaa ah mid dabacsan oo sahlan in la beddelo. Waa u fududahay macaamiishu in ay doortaan K57 yareeya, K67, yareeya K77, yareeya K87, dhimay K97, wax dhimis KA87, wax dhimis KA97, KA107 dhimis, KA127 yareeya.

Daboolista cabbirrada 6 ee yareeyayaasha hal-hal-hal-hal ah iyo cabbirrada 14 ee xawaaraha 2aad iyo 3aad ee xawaaraha, MR taxane helical geared matoorada ayaa si fiican u buuxiya shuruudaha booska awoodda iyo rakibaadda, fikradda qaabaysan ee la xaqiijiyay iyo adag Heerarka tayada ayaa bixiya noocyo kala duwan oo badeecado ah oo leh heerar wanaagsan. saamiga torque iyo gear. Kala duwanaanshiyahan gaarka ah waxa uu u sahlay Marali Marali in uu dejiyo heerar cusub oo dhinaca tignoolajiyada wadista ah.

muuqaalka ugu weyn

1. Awood 0.12KW-160KW

2. Saamiga yareeya 1 / 1.65-1 / 14340; isku darka hoos u dhaca labaad 1:11-1:33818

3. Qulqulka 43-4000 Nm

4. Si buuxda loo xidhay oo la xidhay si aanay boodhka iyo biyaha u soo gelin

5. Waxay qaadataa 16000 saacadood oo keliya in lagu beddelo saliidda markii ugu horreysay.

6. Dusha sare ee gearku waa xiriir buuxa, aagga xoogga waa weyn yahay, qulqulka gudbinta ayaa sarreeya.

7. Waxqabadka meshing ee wanaagsan, gariir hooseeya, buuq yar, gudbinta xasilloon

8. Qaybta sahayda korontada 110/220/380/415/660/690V, 50/60Hz

9. Kiiska IP55 (standard), IP66 (ikhtiyaar)

Qalabka ugu muhiimsan / Agabka ugu muhiimsan

1. Walax bir been abuur ah oo tayadeedu sareyso, sanduuqa birta ah ee birta lagu shubay, daawaynta kulaylka-sare iyo dusha marsho

2. Xawaare lagu xoojiyay gudaha iyo dibaddaba ee mishiinnada korontada ku shaqeeya ee hubiya nolosha dheer iyo yaraynta dayactirka.

3 Qalliinka aamusan waa astaan astaan ah, sidaa darteed taxanaha MR wuxuu sidoo kale bixiyaa jawi shaqo oo raaxo iyo caafimaad leh.

4. Hubi in culeyska shaqada ee dayactirka ugu yar uu yahay qaabka ugu muhiimsan ee matoorka ku habboon. Caadi ahaan waa lagama maarmaan in saliidda macdanta lagu beddelo 16,000 saacadood ka dib marka la shaqeeyo, ama lagu beddelo saliid synthetic ka dib 28,000 saacadood oo shaqo ah.

5. Dhammaan is-beddelka dhererka yareeya, waxay u baahan karaan is-dhexgalka gaarka ah ee IEC si ay u ururiyaan noocyada gawaarida adduunka oo dhan, taas oo aan kaliya siinin macaamiisha doorasho iyo dabacsanaan dheeraad ah. 6. Ku rakibida dabacsan ee jagooyin kala duwan. Unugyada Taxanaha MR waxay ku rakiban yihiin boos kasta oo loo baahan yahay, tusaale ahaan toosan, toosan ama la hakiyey, si loo buuxiyo shuruudaha.

Iibiyaha jumlada gearing ee ku lifaaqan oo leh tiro balaadhan oo ah dhimista Xawaaraha ee matoorrada korantada, madaxyada,xawaaraha yareeya matoorka korantada,iyo matoorrada,iyo waliba khibrada lagu dooranayo midka ugu fiican shuruudahaaga. Waxaanu ku iibinaa xawaaraha dhimista alaabta korantada tiro habbeegsi ah, oo leh saamiyo kala duwan oo la heli karo si loo bixiyo ugu badnaan.

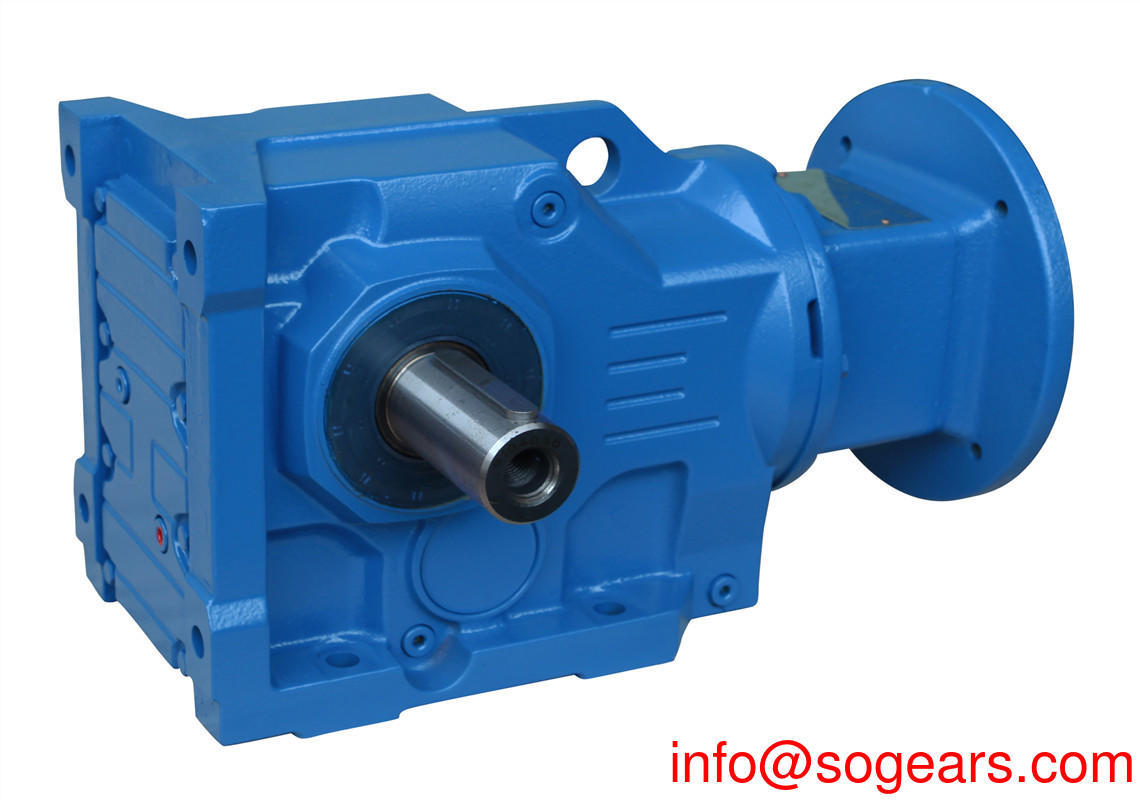

Xawaaraha taxanaha K ee sifooyinka alaabta korantada

1.Highly modular design: Waxaa si fudud loogu qalabayn karaa noocyo kala duwan oo matoor ama qalab kale oo awood. Mashiinka noocan oo kale ah ayaa lagu qalabayn karaa noocyo kala duwan oo matoor koronto ah. Way fududahay in la ogaado xidhiidhka isku dhafan ee ka dhexeeya nooc kasta.

2.Dib-u-dhimista xagasha saxda ah ee mishiinka korantada ee saamiga wax soo saarka qalabka: qaybinta wanaagsan iyo baaxadda ballaaran. Qaabka la isku daray wuxuu sameyn karaa saamiga gear weyn, taas oo ah, wax soo saarku aad ayuu u hooseeyaa.

3.k taxane xawaaraha xawaaraha ee foomka rakibaadda korantada: booska rakibaadda kuma koobna.

4.k taxane xawaaraha xagal qumman ee mishiinka korantada ee wax soo saarka qalabka ayaa leh xoog sare iyo mug yar: jidhka sanduuqa wuxuu ka samaysan yahay bir bir ah oo xoog badan. Gear-ka iyo usheeda dhexe ee marshadu waxay qabataa carburization gaaska iyo habka sifaynta deminta, markaa awoodda wax-qaadista ee mugga cutubkii waa mid sarreeya.

Si badbaado leh oo waxtar leh matoorada korantada u gaabiya ee loo isticmaalo noocyo badan oo warshado iyo mashiinno guri ah oo leh tayo yareeya xawaaraha si sahlan loo isticmaali karo. Balaadhi wareegtada, kontoroolka xawaaraha isha oo ku hagaaji xawaaraha mootada iyadoo leh gears gooryaan ah, xagal qumman iyo dixiridhiyeha xawaaraha wadista matoorka korantada, meerayaasha iyo xawaaraha khadka khadka ee mishiinka korontada.

2019 yareeya xawaaraha tayada sare leh ee alaabada korantada ee qiimaha ugu fiican ee ka imanaya soosaarayaasha gudbinta Shiinaha ee shahaadaysan, alaab-qeybiyeyaasha gawaarida korantada, jumladleyda iyo warshada.

Xirmooyinka xawaaraha 5.k ee matoorka korantada ayaa leh nolol adeeg oo dheer: iyadoo la raacayo shuruudaha xulashada saxda ah (oo ay ku jiraan xulashada isticmaalka habboon ee isticmaalka) iyo isticmaalka caadiga ah iyo dayactirka, nolosha qaybaha ugu muhiimsan ee xawaaraha xawaaraha ee mashiinka korantada (marka laga reebo xirashada qaybo) guud ahaan waa wax aan ka yarayn 20,000 saacadood. . Waxyaalaha la isticmaali karo waxaa ka mid ah saliidaha, saliidda daboolka, iyo xirmooyinka.

6.k taxanaha xagasha saxda ah ee mishiinka korantada ee wax soo saarka qalabka ayaa leh qaylo hoose: qaybaha ugu muhiimsan ee xawaaraha xawaaraha ee mashiinka korantada ayaa ah mashiinka saxda ah ee la isku dhejiyey oo la tijaabiyey, sidaas awgeed xawaaraha xawaaraha ee mashiinka korantada ayaa leh buuq yar.

7.k taxane xawaaraha dhimista ee matoorka korantada ayaa leh waxtar sare leh: hufnaanta hal nooc oo aan ka yarayn 95%. 8. U adkeysan kara culeysyada shucaaca ee waaweyn.

Hordhac

Qaabka iliga ee qalabka wax-yaraha ee Spiral bevel gear ee matoorka korantada waa qaab qaanso ah, guud ahaanna waa la duubay, sida qaab dallad, sidaas awgeed magaca Spiral bevel gear yareeyaha mishiinka korontada.

Qalab-dhimista qalabka wax-soo-saarka ee matoorka korantada waa nooc ka mid ah qayb gudbinta oo si adag loo kaxeyn karo oo leh buuq hoose iyadoo loo eegayo saamiga gudbinta deggan. Waxay ku leedahay magacyo kala duwan gobollo kala duwan, oo sidoo kale loo yaqaan 'Spiral bevel gear reducer' oo loogu talagalay korantada korantada, yareeyaha qalabka korantada ee mashiinka korantada, yareeyaha qalabka korantada ee mashiinka korantada, gear bevel gear, Spiral bevel gear yareeyaha matoorada korantada, iwm.

Calaamadaha

Qalabka loo yaqaan 'Spiral bevel gear' ee gudbinta matoorka korantada ayaa leh hufnaan sare, saamiga gudbinta xasilloon, isugeynta weyn ee isku-dhafka ah, awoodda wax-soo-saarka sare, gudbinta siman oo siman, hawlgal la isku halleyn karo, qaab-dhismeedka is haysta, badbaadinta tamarta, badbaadinta booska, iska caabbinta xirashada, nolosha adeeg dheer iyo buuq yar.

Waxaa ka mid ah gudbinta farsamada ee kala duwan, hufnaanta gudbinta ee hoos u dhigista qalabka Spiral bevel ee matoorada korantada ayaa ah kan ugu sarreeya, kaas oo faa'iidooyin dhaqaale oo weyn u leh dhammaan noocyada gudbinta, gaar ahaan gudbinta awoodda sare; Qaybaha gudbinta ee qaybaha gudbinta ee loo baahan yahay gudbinta isku midka ah ayaa ah kuwa ugu badan ee kaydinta, marka loo eego suunka, Meesha loo baahan yahay silsiladda gawaarida waa yar tahay; Hoos-u-dhaca qalabka Spiral bevel ee saamiga gudbinta korantada ayaa si joogto ah u deggan, saamiga gearkuna waa mid deggan. Badanaa waa shuruudaha aasaasiga ah ee waxqabadka gudbinta ee gudbinta noocyada kala duwan ee qalabka farsamada; Qalabka Spiral bevel gear yareeya matoorka korantada wuxuu u shaqeeyaa si la isku halleyn karo wuxuuna leeyahay nolol adeeg dheer.

faahfaahinta

Qalab-dhimista qalabka Spiral bevel ee loogu talagalay sawir qaadaha mashiinka korantada

Qalab yareeya qalabka korantada ee qalabka korantada (6 sawir)

Waxaa jira dhexroor 10mm-1600mm, modules 1-36 modules, Spiral bevel gear yareeyaha matoorada koronto leh buundooyinka saxda ah GB5 - GB8. Marka loo eego habka naqshadeynta, habka wax-soo-saarka iyo qalabka wax-ka-qabashada ee mashiinka korantada ee Spiral bevel, yareeyaha qalabka korantada ee korantada waxaa loo qaybin karaa Jarmal Klingberg Spiral bevel gear yareeyaha mashiinka korantada , Swiss Olympus Spiral bevel gear yareeya mashiinka korantada, sida caadiga ah loo yaqaan Klingberg Spiral bevel gear yareeya matoorada korantada, Gleason Spiral bevel gear yareeyaha matoorada korantada iyo Olympus Spiral bevel gear yareeya matoorada korantada. Waxaa jira farqi yar oo u dhexeeya noocyadan kala duwan ee qalabka wax-yareeya ee Spiral bevel ee matoorada korantada, laakiin cabbirada ugu muhiimsan ayaa weli leh waxyaabo badan oo ay isaga egyihiin. Marka loo eego jawiga codsiga ee qalabka wax lagu dhimo ee Spiral bevel ee matoorka korantada, cabirrada kala duwan ayaa sidoo kale aad u kala duwan.

Marka loo eego jawiga isticmaalka kala duwan, yareeyaha qalabka Spiral bevel ee mootada korantada waxaa loo qaybin karaa silsilad centrifugal bevel gear taxane ah Spiral bevel gear yareeya mishiinka korantada, dhuxusha dhuxusha tooska ah ee mashiinka korantada. Mashiinnada birta ah ee rogroga ee matoorka korantada , Taxanaha xamuulka taayirrada Spiral bevel gear yareeya mishiinka korantada, isku dhafka dhinaca isku dhafka ah ee loo yaqaan 'Spiral bevel gear' ee mashiinka korantada, Hooseeyaha DCY loogu talagalay mashiinka korantada, mashiinka sawiridda fiilada taxanaha ah Spiral bevel gear reducer fo r mishiinka korantada, mishiinka sibidhka toosan ee mishiinka mishiinka korontada matoorada, tuubooyinka naxaasta alxanka leh ee matoorada korantada, Mashiinada samaynta tuubada Spiral bevel yareeyaha matoorada korantada iyo taxane kale oo ah Spiral bevel gear yareeya matoorada korantada.

codsiga

Qalab-dhimista qalabka wax-soo-saarka ee matoorada korantada waxaa si ballaaran loogu isticmaalaa gudaha iyo kuwa caalamiga ah ee mashiinnada petrochemical, qalabka mashiinka kala duwan, qalabka farsamaynta farsamada ee kala duwan, mashiinnada injineernimada, qalabka birta, mashiinnada duubista, mashiinnada macdanta, mashiinnada macdanta dhuxusha, mashiinnada dunta, mashiinnada badda, dhismaha maraakiibta. warshadaha, aerospace, forklift, wiish, hoos u dhigista, wax soo saarka diyaaradaha iyo warshado kale oo badan. Qalabka loo yaqaan 'Spiral bevel gear yareeya' ee mashiinka korantada waxaa loo adeegsadaa qalabyo farsamo oo kala duwan wuxuuna soo bandhigaa waxqabadkiisa ugu wanaagsan. Waxaa si qoto dheer u saameeya soosaarayaasha qalabka hawada, mashiinnada maraakiibta, warshadaha mishiinada injineernimada, warshadaha qalabka birta, warshadaha birta rogroga, warshadaha birta duuban, roodhida, warshadda mashiinada biraha, warshadda mashiinada macdanta, macdanta dhuxusha, warshadda mishiinada petrochemical oilfield , Warshada mishiinada dunta, warshada qalabka mishiinada, shirkada qalabka, shirkada wiishka, warshada dayuuradaha, warshada dhimista, warshada mashiinada dhuxusha, warshada fudud ee warshada, warshada duubista, warshada qalabka birta, warshada qalabka birta iyo macaamiisha kale jecel.

Farqiga u dhexeeya hypoid bevel gear

Qalab-dhisiyaha qalabka korantada ee matoorrada korantada iyo gears-ka hypoid-ka ayaa ah hababka gudbinta ugu weyn ee loo adeegsado dhimayaasha waaweyn ee baabuurta. Waa maxay farqiga u dhexeeya?

Sida ku cad shaxanka 2(a), qalabka wax-dhimista ee Spiral bevel gear ee matoorka korantada waxa uu leeyahay faashashihiisa ugu muhiimsan iyo kuwa la wado oo isku xidha hal dhibic, iyo xagasha isgoysku waxa uu noqon karaa mid aan sabab lahayn. Si kastaba ha ahaatee, inta badan dariiqyada wadista baabuurta, labada marsho ee u dambeeya waxa loo habeeyey xagal 90° ah. jidka. Sababo la xiriira saamaynta isku-dhafka ee wejiyada dhamaadka ilkaha, ugu yaraan laba ama in ka badan oo ilig ah ayaa isku mar la wada miidhan. Sidaa darteed, Spiral bevel gear gear for motor koronto waxay u adkeysan kartaa culeys weyn, ilkuhuna isku mar iskumar kuma wada dhaqmaan dhererka iliga oo dhan, laakiin si tartiib tartiib ah ilkaha. Mid ka mid ah cidhifku wuxuu si joogto ah u leexdaa dhinaca kale, isaga oo ka dhigaya inuu si habsami leh u shaqeeyo, xitaa xawaaraha sare, qaylada iyo gariirku waa yar yihiin.

Farqiga udhaxeeya qalabka wax lagu dhimo ee Spiral bevel ee matoorka korantada iyo qalabka laba-geesoodka ah

Sida ku cad sawirka 2(b), gear hypoid waxa uu leeyahay meel banaan oo isku xidha faashashka ugu weyn iyo kuwa la wado, xagasha goynta booskuna waa xagal 90° ah. Shafka marshoku waxa uu leeyahay kor u kac ama hoos (oo si la mid ah loo tixraaco meel sare ama hoose) marka loo eego shafka marsho ee la wado. Marka dhimistu ku filan tahay, hal shafka marsho ayaa loo gudbin karaa shafka kale ee geerka. Tani waxay suurtogal ka dhigaysaa in la habeeyo xadhkaha is haysta ee labada dhinac ee qalab kasta, taas oo faa'iido u leh kor u qaadida qallafsanaanta taageerada iyo hubinta meshing saxda ah ee geerka, taas oo kordhinaysa nolosha qalabka. Waxay ku habboon tahay dhidibyada wadista.

Si ka duwan kiiskii uu gear gear-gaabeedka helical-ku-gudbida dhidibka labada marsho sida in xaglaha helix ee ugu weyn iyo marsho wadid waa siman yihiin, leexashada dhidibka labada marsho hypoid waa sida in xagal helix marsho ka weyn yahay kaxeeyey. xagal helix gear. Sidaa darteed, module-ka caadiga ah ee labada lamaane ee bevel bevel hypoid waa siman yihiin, laakiin wejiga dhammaadka wejigu waa mid aan sinnayn (dhammaadka modules-ka-dhammaadka ee qalabka wadista wuu ka weyn yahay dhammaadka wejiga qalabka la wado). Tani waxay u oggolaanaysaa qalabka wadista ee qalabka laba-geesoodka ah ee laba-geesoodka ah si uu u yeesho dhexroor ka weyn kana xoog iyo qallafsanaan ka wanaagsan yahay qalabka wadista ee u dhigma ee Spiral bevel gear yareeya wadista korontada. Intaa waxaa dheer, tan iyo dhexroorka qalabka wadista iyo xagasha helix ee gudbinta qalabka hypoid bevel labaduba waa weyn yihiin, cadaadiska korka iliga ee xiriirka ayaa hoos u dhacaya noloshana waa la hagaajiyay.

Si kastaba ha noqotee, marka gudbintu ay yaraato, qalabka wadista gudbinta marshada bevel-ka-laba-geesoodka ah waa mid aad u weyn marka loo eego qalabka wadista ee qalabka wax-yareeya ee Spiral bevel ee matoorka korantada. Waqtigaan, Spiral bevel gear gear dhimis ee matoor koronto waa macquul.

Qalabka loo yaqaan 'Spiral bevel gear' ee gudbinta matoorka korantada ayaa leh hufnaan sare, saamiga gudbinta xasilloon, isugeynta weyn ee isku-dhafka ah, awoodda wax-soo-saarka sare, gudbinta siman oo siman, hawlgal la isku halleyn karo, qaab-dhismeedka is haysta, badbaadinta tamarta, badbaadinta booska, iska caabbinta xirashada, nolosha adeeg dheer iyo buuq yar. Hooseeyaha Spiral bevel gear yareeya mishiinka korontada

Qalab-dhimista qalabka korantada ee mashiinka korantada waxaa loo qaybin karaa nooca centrifugal nooca budada kala-soocida taxanaha Spiral bevel gear reducer for motor koronto, dhuxusha dhuxusha tooska ah Qalab yareeya mashiinka korantada, xawaaraha isbedbeddelka baabuurta ee xawaaraha gudbinta ee isdabajoogga qalabka korontada Matoorka korantada, isku dhafka dhinaca isku dhafka ah ee loo yaqaan 'Spiral bevel gear gear' ee matoorka korantada, Diiriyaha DCY ee mashiinka korantada ee korantada, DBY yareeyaha qalabka korantada ee korantada gear yareeya motor koronto, sibidhka miraha toosan Spi ral bevel gear yareeya matoorka korantada, mashiinka qodista qodista saliida taxanaha Spiral bevel gear yareeya matoorka korantada, mishiinnada injineernimada taxanaha mashiinnada qalabka wax lagu dhimo ee korantada Qalabaynta mashiinka korantada ee mashiinka korantada, mishiinada samaynta tuubada Spiral bevel gear yareeya mishiinka korantada matoorada korontada.

Sida soo saaraha hormuudka ah ee xawaaraha dhimista ee mishiinka korontada. Waxaan joognay ilaa 1992, waxaanan bixinaa isku halaynta, daacadnimada iyo alaabada korantada oo tayo sare leh. Xawaaraha yareeya matoorada korantada, kontaroolada xawaaraha, gearmotors iyo gears waa uun qaar ka mid ah xawaaraha yareeya alaabta korantada ee aanu bixino.

Salaan Wanaagsan,

Cherry Zhang (Waaxda Iibka; Waa la waayey.)

NER GROUP CO., LIMITED

Yantai Bonway Manufacturer Co., Ltd.

Tel: + 86-535-6330966

Taleefoonnada: + 86-18865558975

www.planetary-xawaaraha dhimaha ee motor koronto.com

https://twitter.com/speed reducer for electric motormotor

https://www.facebook.com/sogears1993

Viber / Line / Whatsapp / WeChat: 008618865558975

E-mail:

Ku dar: No.5 Wanshoushan Wadada Yantai magaalada Gobolka Shandong, Shiinaha

Howlaha ugu wanaagsan ee laga helo khabiirkeena gudbinta ilaa toos booskaaga.

Our Service

Nala soo xiriir

Yantai Bonway Manufacturer Co.ltd

ANO.160 Changjiang Road, Yantai, Shandong, Shiinaha(264006)

T + 86 535 6330966

W + 86 185 63806647