BWD9-23-75 BWD9-29-75 BWD9-35-55 BWD9-43-55 BWD9-59-45 BWD9-71-37 BWD9-87-30

Qalabka loo yaqaan 'Cycloidal pinwheel reducer' waa qalab gudbinta sheeko cusub oo qaadanaya mabda'a gudbinta meeraha ee KHV oo leh farqi yar oo ilig ah. Nidaamka gudbinta ayaa ah sidan soo socota: labbo gacmeed oo laba-cirifood ah oo barokacay 180 digrii ayaa lagu rakibay wiishka galinta, laba waab oo duuban oo loo yaqaanno gacmo wareegaya ayaa lagu rakibay gacmo-mareenka si loo sameeyo farsamaynta H. Godadka dhexe ee labada cycloids waa eccentric Tartankii loogu talagalay garabka gacanta sare waa la xirxiray, gawaarida cycloidal waxay ku dhejisaa cirbadda irbadda si ay u sameyso farsamo dhimis gudaha ah oo leh farqi hal ilig ah.

Qalabka wax lagu dhimo ee loo yaqaan 'Cycloidal pinwheel' ayaa si ballaaran loogu adeegsadaa birta, macdanta, qaadista, gaadiidka, sibidhka, dhismaha, kiimikada, daabacaadda iyo dheehida, dawooyinka, warshadaha cuntada iyo ilaalinta deegaanka. Ku habboon heerkulka deegaanka shaqada ee -40 ℃ -40 ℃, hoosta culeyska iyo xawaaraha lagu qiimeeyay, kororka heerkulka barkadda saliidda ee soo-dejintu kama badnaan 60 ℃, heerkulka saliidda ee ugu badana kama badna 80 ℃.

Qalabka loo yaqaan 'Cycloidal pin gear reducer' waa qalab gudbineed oo cusub oo khuseeya mabda'a gudbinta meeraha isla markaana korsada ilkaha biinka loo yaqaan 'pincloidal pin pin'. Aaladda gudbinta oo dhan ee reducer-ka loo yaqaan 'cycloid reducer' waxaa loo qaybin karaa saddex qaybood: qayb aqbasho, qayb hoos u dhac ah, iyo qayb soo saar. Gacan laba-geesood leh oo baraf leh oo leh 180 ° ayaa lagu rakibay wiishka gelinta, laba waji oo isku-dhafan oo loo yaqaan 'swing hubka' ayaa lagu rakibay gacmo-mareenka si ay u sameeyaan farsamaynta H. Godadka dhexe ee labada cycloids ayaa ah culaysyada gacanta ee lulaya ee kore ee shaati-gacmeedka. Si loo yareeyo khilaafaadka, hoos u dhaca ku yimaadda saamiga xawaaraha yar, wiishka cycloidal wuxuu laalaabaa tiro ilkaha cirbadda oo wareegsan lagu habeeyay qalabka irbadda si uu u sameeyo farsamayn hoos udhaca muruqyada gudaha oo leh farqiga ilig ee hal ilig. , Cirbadda cirbadda ee cirbadda ayaa lagu dhejiyaa ilig cirbadda).

Hordhac kooban oo:

Markay usheeda wareejintu ku wareegeyso shaashadda wareegga hal wareeg, ayada oo ay ugu wacan tahay sifooyinka astaamaha iligga kore ee mootada loo yaqaan 'cycloidal wheel' iyo xaddidaadda qalabka irbadda ee qalabka cirbadda, dhaqdhaqaaqa gawaarida cycloidal wuxuu noqonayaa dhaqdhaqaaq diyaarad leh labadaba kacaan iyo wareeg. Marka usheeda dhexe ee wax soo gelintu ay u rogmato hal wareeg, shaati gacmeedku sidoo kale wuxuu wareejiyaa hal wareeg, shaagagga loo yaqaan 'cycloidal wheel' ayaa hal ilig u rogaya dhinaca ka soo horjeedka si loo helo hoos u dhac. Kadib, iyadoo la kaashanayo habka wax soo saarka W, dhaqdhaqaaqa wareegga xawaaraha hoose ee wareegga cycloidal waxaa loo gudbiyaa mashiinka wax soo saarka iyada oo loo marayo mashiinka pin. Si loo helo xawaare wax soo saar hoose.

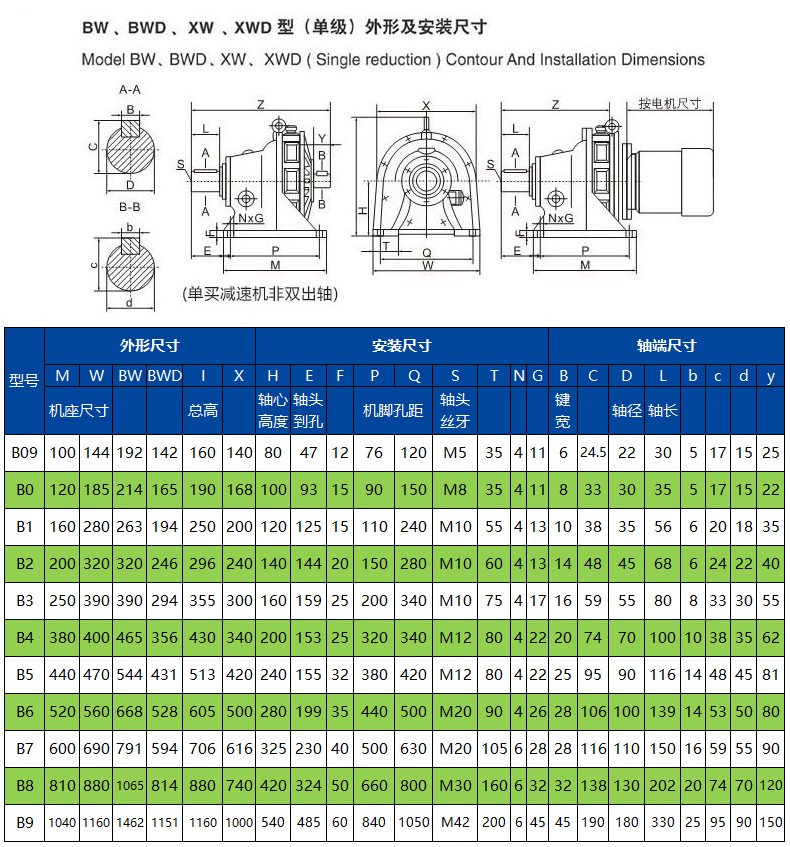

Faahfaahinta hoos u dhigista BWD ee loo yaqaan 'cywheid pinwheel pinwheel'

1. Mabda'a qaabdhismeedka: gudbinta meeraha, waxay qaadataa qalabka loo yaqaan 'cycloidal gear' si loogu miiro ilkaha cirridka, sameynta farqi yar oo ilkaha ah oo ka mid ah farsamooyinka dhimista meeraha, kaas oo u gudbiya xawaaraha soo gelinta si wada jir ah iyo dib u dhac iyo hoos u dhac.

2. Astaamaha: Saamiga xawaaraha sarreeya, mugga yar ee leh mabda'a gudbinta meeraha, ma jiro xoog axial ah.

3. Nooca rakibida iyo qaabka wax soo saarka: nooca aasaasiga, nooca flange, soo saarida usheeda dhexe adag.

4. Qaabka soo galinta: mootada tooska ugu xiran, usheeda adag, nooca flange galinta.

5. Saamiga gudbinta:

Heerka kaliya: 7,9,11,17,23,25,29,35,43,47,59,71,87

Laba -cirifoodka: 121,187,289,319,473,595,731,841,1003,1225,1505,1849,2065,2537,3481,5133,7569

Heerka 3: 2057-658503

6. Waxtarka celceliska: 90% heerka koowaad iyo 88% heerka labaad.

7. Qaabka BWD ee hoos u dhigga cycloid:

Marxalad keli ah oo aan lahayn saamiga xawaaraha: BWD0, BWD1, BWD2, BWD3, BWD4, BWD5, BWD6, BWD7, BWD8, BWD9

Features:

Waxay gaari kartaa saamiga hoos u dhigista sare ee 1:87 iyo gudbinta wax ku oolnimada heerka sare ee hal mar oo ka badan 90%. Haddii gudbinta marxalado badan la isticmaalo, saamiga dhimista ayaa sii weynaan doona. Qiyaasta dhimista gudbinta heerka koowaad waa 9 ~ 87, saamiga dhimista gudbinta labada marxaladood waa 121 ~ 5133, iyo isku dhafka marxaladaha badan wuxuu gaari karaa tobanaan kun. Iyo nidaamka ka-qaybgalka pin-ilkaha nooca gacmaha is-jiidashada, dusha meshing-ku ma laha simbiriirixan qaraabo ah, markaa waxtarka dhimista heerka koowaad waa 94%. Qaab dhismeed is haysta iyo cabbir yar. Sababtoo ah mabda'a gudbinta meeraha, qulqulka wax-soo-saarka iyo soo-saarka wax-soo-saarka ayaa ku yaal dhidib isku mid ah, si cabbirka qaabka uu u noqon karo mid yar intii suurtagal ah. Orod macaan iyo buuq yar. Ilkaha cirbadda Cycloid waxay leeyihiin tiro badan oo ilko isku-xidha, iskuxiran weyn oo isku-dhafan iyo habka dheellitirka makaanikada, si gariirka iyo qaylada loo xaddido ugu yaraan. Inta lagu jiro shaqada, waxaa jira dhowr lamaane oo ilko ah oo isku mar wada xiriiraya, oo leh shahaado iskudhac weyn, hawlgal xasilloon, awood xad dhaaf ah, gariir hoose iyo buuq, iyo buuq yar oo loogu talagalay moodooyinka tilmaamo kala duwan.

Isticmaal lagu kalsoonaan karo iyo nolol dheer. Sababtoo ah qaybaha ugu muhiimsan waxay qaataan walxaha birta leh, xoog sare waxaa lagu helaa daawaynta deminta (HRC58~62), iyo qayb ka mid ah xiriirinta gudbinta waxay isticmaashaa isjiidjiid, markaa waa waara oo waxay leedahay nolol dheer. Sababtoo ah qaybaha ugu muhiimsan waxay ka samaysan yihiin dawaynta daminta birta (HRC58-62), ka dibna si fiican loo dhulkay, iyo ilkaha cycloidal iyo gacmo-gacmeedka irbadda ayaa la dahaadhiyay oo loo kala qaadaa ilkaha irbadda si ay u sameeyaan lammaane is-jiidjiid ah, isku-dheellitirka is-burburku waa yar, si aanay u jirin simbiriirixan qaraabo aagga meshing. Xiro iyo dillaac aad u yar, si ay u waarto. Naqshad macquul ah, dayactir ku habboon, kala diris fudud iyo rakibid, tirada ugu yar ee qaybaha iyo sifaynta fudud ayaa ka dhigaysa yareeyaha cycloid si qoto dheer loogu kalsoon yahay isticmaalayaasha. Marka la barbar dhigo wax-yareeyayaasha kale ee isla awoodda ah, miisaanka iyo mugga ayaa ka yar 1/3. Iyada oo ay ugu wacan tahay gudbinta meeraha, qulqulka wax-gelinta iyo soo-saarka wax-soo-saarka ayaa ku yaal dhidib isku mid ah si loo helo cabbirka ugu yar ee suurtogalka ah.

Tilmaamaha isticmaalka

isticmaalaan,

Qalabka loo yaqaan 'Cycloidal pin gear reducer' wuxuu qaataa mabaadii'da cows-ka loo yaqaan 'meshing pinhing meshing' iyo gudbinta meeraha, sidaa darteed waxaa badanaa loo yaqaan 'cycloid reducer'. Qalabaynta qalabka loo yaqaan 'pincloid pin gear gear reducer' ayaa si ballaaran loogu isticmaali karaa batroolka, ilaalinta deegaanka, warshadaha kiimikada, sibidhka, gaadiidka, Dharka, dawooyinka, cuntada, daabacaadda, qaadista, qodista, macdanta, metallurgy, dhismaha, dhalinta korontada iyo warshadaha kale, wadista ama yareynta qalab, mishiinku wuxuu u qaybsan yahay qaab toosan, toosan, laba-wiif iyo qaabab isugusoo urursan oo si toos ah isugu xidhan. Qaab-dhismeedkeeda gaarka ah ee xasilloon ayaa beddeli kara kuwa yareeya qalabka maareynta qalabka wax lagu gooyo iyo kuwa dixirma dixiriga marar badan. Sidaa darteed, waxyaabaha yareeya cycloid-ka meeraha ayaa si ballaaran loogu adeegsadaa warshado iyo beero kala duwan guud ahaanna waa la soo dhoweeyaa dadka isticmaala.

Xaaladaha Isticmaalka:

1. Qalabka wax lagu dhimo ee loo yaqaan 'Cycloidal pinwheel' ayaa loo oggol yahay in loo isticmaalo xaaladaha shaqada ee joogtada ah, iyadoo loo oggolaanaayo rogidda iyo rogista labadaba. Moodooyinka qaar ee yareeyayaasha loo yaqaan 'cycloid' ayaa kaliya u oggolaanaya rogidda hal-waddo.

2. Xawaaraha lagu qiimeeyay shaati-soo-gelinta waa 1500 rpm. Marka awoodda wax galintu ka weynaato 18.5 kW, waxaa lagu talinayaa in la isticmaalo matoor 6-pole oo leh 960 rpm.

3. Meelaha shaqada ee hoos u dhigga lagu rakibay cycloid dhammaantood waa jiif. Xagalka ugu sarreeya ee xagalka jiifka ah inta lagu jiro rakibidda guud ahaan wuu ka yar yahay 15 °. Markay dhaafto 15 °, talaabooyin kale waa in laqaato si loo hubiyo saliid kufilan ugana hortagto daadashada saliida.

4. Mashiinka wax soo saarka ee cycloid reducer laguma xakamayn karo xoog weyn oo faasli ah iyo xoog shucaac ah, waana in la qaadaa tillaabooyin kale marka ay jiraan xoog weyn oo foorar iyo xoog radial ah.

saliidayn:

1. Hoos u dhigga cycloid-ka jiifku wuxuu korsadaa saliidda barkadda saliidda iyadoo lagu jiro xaalado caadi ah, heerka saliidda waxaa lagu hayn karaa bartamaha daaqadda aragga saliidda. Marka xaaladaha shaqadu xun yihiin oo heer kulka deegaanku sarreeyo, saliidda wareega ayaa la isticmaali karaa.

2. Soo-saaraha loo yaqaan 'Cycloid pinwheel reducer' guud ahaan wuxuu doortaa 40 # ama 50 # saliid saliid farsamo heerkulka qolka. Si loo hagaajiyo waxqabadka hoos u dhigaha loona kordhiyo nolosha adeegga cycloid pinwheel reducer, waxaa lagugula talinayaa inaad isticmaasho 70 # ama 90 # cadaadis xad dhaaf ah. Saliida, saliida saliidda waa in dib loo tixgeliyaa marka lagu shaqeynayo xaaladaha heerkulka sare iyo hooseeya.

3. Ku rakibida tooska ah ee soo dejiyaha cycloid meeraha waa inay si adag uga hortagtaa bamka saliida inuu gooyo saliida si looga fogaado waxyeelo soo gaadha qaybaha reducer-ka.

4. Markaad shidaal qaadanaysid, waxaad u rogi kartaa daboolka neefsashada qaybta sare ee kursiga si aad shidaal uga qaadato. Markaad saliida daadinayso, leexo godka godka hoose ee kursiga weyn si aad uga daadatid saliida wasakhda ah. Ma jiro wax saliid ah oo saliideeya gudaha warshadda.

5. Saliid cusub waa in la beddelaa 100 saacadood ka dib hawlgalka shidaal ee ugu horreeya, (oo nadiifi saliidda wasakhda ah ee gudaha ku jirta), ka dibna sii wad in ay shaqeyso ka dib. Beddel lixdii biloodba mar (nidaamka shaqada ee 8-saacadood ah). Haddii xaaladaha shaqadu xun yihiin, waqtiga beddelka saliidda si habboon ayaa loo gaabin karaa. Tababarku wuxuu caddeeyay in nadaafadda iyo saliidda beddelidda ee soo-dejiyaha (sida 3-6 bilood) ay door muhiim ah ka ciyaaraan kordhinta nolosha adeegga soo-dejiyaha. Saliida saliidda waa in si joogto ah loogu daraa inta la isticmaalayo.

6. Soo-saaraha warshadda ayaa la duubay lana beddelay lixdii biloodba mar. Dufanka wuxuu qaataa aluminium disulfide-2 # ama 2L-2 # dufanka saliidda lithium-ku-saleysan.

rakibida:

rakibida:

1. Marka la rakibayo isku-xidhka, wiishka suuliga, sprocket-ka iyo qaybaha kale ee isku xidhka ee ku yaal mashiinka wax soo saarka ee cycloid reducer-ka, garaacista tooska ah lama oggola, maxaa yeelay qaab-dhismeedka usheeda dhexe ee soo-saaraha ayaa soo-celinyuhu u adkaysan kari la’yahay awoodda garaacista asalka. Waxaad u isticmaali kartaa godka godka dhamaadka usheeda dhexe si aad ugu maroojiso shayga qaybta isku xidhka.

2. Dhexroorrada usheeda dhexe ee wiishka wax soo saarka iyo wiishka gelinta waxay la jaan qaadayaan GB1568-79.

3. Xirayaasha indhaha ee hoos u dhaca waxay kaliya u taagaan inay yareeyaan.

4. Marka hoos-u-dhiguhu ku rakiban yahay salka, kor u qaadista xariiqda rakibidda xariiqda soo-saaraha, heerka iyo cabirka ku habboon ee qaybaha isku xiran waa in lagu cabbiraa. Isku-xirnaanta fallaadhaha loo yaqaan 'usheeda dhexe' waa inaysan ka badnayn inta la oggol yahay ee isku-xidhka.

5. Marka hoos-u-dejiyaha la qiyaasi karo, waxaa lagu fulin karaa fallaarayaasha birta ama baarayaasha birta lagu rido. Dhererka spacers-ka kama badna seddex, waxaana sidoo kale lagu fulin karaa bir qandaraas ah, laakiin dib-u-hayaha waa in lagu beddelaa kala-soocyada fidsan ka dib hagaajinta.

6. Isku habeynta barkinta barkinta waa inay ka fogaataa inay keento cillad jirka mashiinka, waana in si siman loogu hagaajiyaa labada dhinac ee boodhadhka aasaaska, masaafada labada dhinacna waxay noqon kartaa mid ku filan si loogu oggolaado qulqulka biyaha inuu si xor ah u qulqulo inta lagu guda jiro waraabka.

7. Waraabinta wasakhda sibidhka waa inay ahaato mid cufan, oo aan lahayn xumbo, faaruq iyo cilado kale.

Qaab-dhismeedka hoos-u-dhigga cycloid-ka-jiifka ah:

Dhammaan qaab-dhismeedka gudbinta ee hoos-u-dhigga pinwheel-ka hooseeya ee loo yaqaan 'cycloidal pinwheel reducer' ayaa loo qaybin karaa saddex qaybood: qayb aqbasho, qayb hoos u dhac ah, iyo qayb soo saar. Qaab dhismeedka galinta waa qaybta xawaaraha sare leh, oo ku xiran matoorka gelinta (mootada); qaybta wax soo saarku waa hoos u dhige. Qeybta xawaaraha-hoose, mashiinka wax soo saarka wuxuu ku xiran yahay qalabka uu adeegsadaha u baahan yahay inuu ku dhex maro jeexjeexa, isku xirnaanta, saxanka isku xiraya, iwm.

Nidaamka hal-ku-dhigga ah ee hoos-u-dhigga cycloid:

Jaangooyaha jiifka ah ee loo yaqaan 'cycloidal pinwheel reducer' oo leh saxanka cagta ee hoos u dhigaha wuxuu qaadanayaa heerarka warshadeed ee khuseeya Wasaaradda Mashiinka iyo Wasaaradda Warshadaha Kiimikada; xarafka W waxaa lagu qeexay qaabka magacaabista, macnahiisuna waa in la isticmaalo xarafka ugu horeeya W ee alifbeetada Shiinaha ee pinyin si loo muujiyo. Marka loo eego qaab dhismeedka soo-dejiyaha, soo-dejiyeha biraha loo yaqaan 'cycloidal pinwheel reducer' wuxuu leeyahay moodooyinka soo socda: BWD XWD BWY XWY BW XW iyo wixii la mid ah.

Baahinta arjiga iyo baaxadda hal -beegga soo-gaabiyo hoos-u-dhaca:

Hal-marxaladda jiifka ah ee loo yaqaan 'cycloidal pinwheel reducer' ayaa si ballaaran loogu isticmaali karaa farsamaynta yareynta mashiinnada gudbinta ee kala duwan, sida: mashiinada hoing-ka, mashiinnada gaadiidka, mashiinnada macdanta, mashiinnada qalliinka, mashiinnada baatroolka, mashiinnada dharka, daabacaadda iyo mashiinnada midabaynta, mashiinnada warshadaha fudud, Mashiinnada cuntada, mashiinnada dawooyinka, mashiinnada caagga ah, mashiinnada caagga ah, mashiinnada baakadaha, mashiinnada biirka, mashiinnada dhismaha waddooyinka, mashiinnada ilaalinta deegaanka, mashiinnada hadhuudhka iyo saliidda, iwm.

Shuruudaha:

1. Qalabka loo yaqaan 'Cycloidal pinwheel' ayaa loo oggol yahay in loo isticmaalo xaaladaha joogtada ah ee 24-ka saac ee shaqada, waxaana loo oggol yahay inay ku ordaan labada dhinacba xagga hore iyo gadaal. Wareegga mashiinka wax soo saarka ee halbeegga cycloid reducer-ka ayaa ka soo horjeedda kan birta laga soo galo, iyo wareegga mashiinka wax soo saarka ee labalaabka marxaladda cycloid wuxuu la mid yahay wareegga mashiinka gelinta.

2. Mashiinka wax soo saarka ee cycloid reducer ma qaadi karo xoog axial. Xawaaraha la qiimeeyay ee wiishka galku waa 1500 rpm. Marka awoodda wax soo gelintu ay ka weyn tahay 18.5 kW, waxaa lagugula talinayaa inaad isticmaasho matoor 6-pole ah oo leh 960 rpm.

3. Meelaha shaqada ee hoos u dhigga lagu rakibay cycloid dhammaantood waa jiif. Xagasha janjeer ee ballaadhan ee ballaadhan inta lagu guda jiro rakibidda guud ahaan way ka yar tahay 15 °. Markay dhaafto 15 °, talaabooyin kale waa in laqaato si loo hubiyo saliid kufilan ugana hortagto daadashada saliida.

4. Mashiinka wax soo saarka ee cycloid reducer laguma hoos gelin karo xoog axial weyn iyo xoog shucaac ah. Tillaabooyin kale waa in la qaadaa markay jiraan xoog faasas ah iyo xoog shucaac ah.

5. Xaaladaha ay dhici karto in culeys badani ka dhasho, waa in la rakibaa qalab difaaca culeyska xad dhaafka ah.

6. Xilliga saameynta sare, gariirka ama bilowga soo noqnoqda, salka iyo aasaaska waxaa loo baahan yahay in lagu xoojiyo biinanka meelaynta (is-diyaarshay) marka lagu daro boodhadhka cagta ee isku xidhka.

7. Markaad isticmaaleyso sproket-ka gudbinta, ha u dabcin silsiladda ilkaha si aad ah, haddii kale saameyn ayaa la soo saari doonaa markii la bilaabayo.